Benchtop CNC Router Kit with 2×4 Table Size for Sale

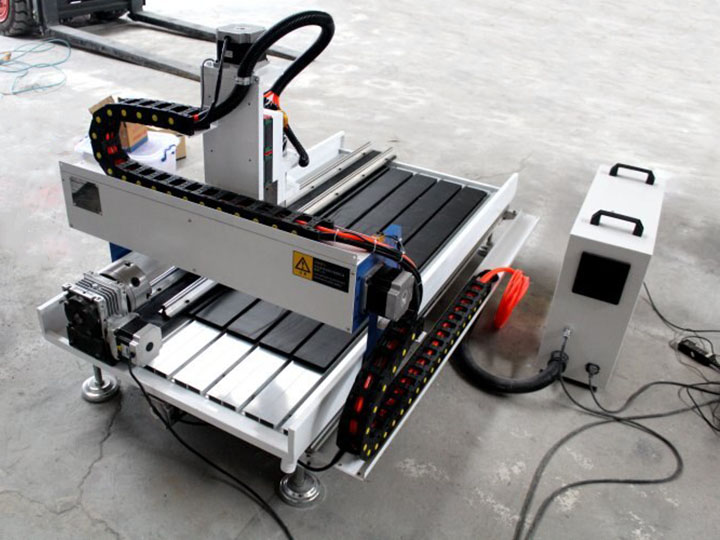

STG6012 benchtop CNC router machine comes with a 2×4 T-slot working table, iron cast steel structure, water cooling spindle, Mach3 control system, Fuling inverter, stepper motor, and Leadshine driver. X, Y, and Z axis by Taiwan TBI ball screw. The 2×4 CNC router kit can also be equipped with a rotary 4th axis for 3d machining.

- What is a Benchtop CNC Router Kit?

- 2x4 Benchtop CNC Router Kit Features

- Advantages of Benchtop Models

- Technical Parameters of Benchtop CNC Router Kit with 2x4 Table Size

- 2x4 Benchtop CNC Router Kit Applications

- 2x4 Benchtop CNC Router Kit Projects

- 2x4 CNC Router Table Package

- Benchtop CNC Router Service

- Considering Factors

What is a Benchtop CNC Router Kit?

A benchtop CNC router kit is a compact CNC machine designed for milling, cutting, and engraving various materials with precision. It comes with different bed size options and the 2×4 is one of the common configurations used in small to medium industries.

The term “benchtop” refers to the router’s primary pathway of machining. The routers are designed to be set up on a workbench or table. Despite the compact size, these routers offer decent cutting capacity.

Benchtop CNC router kit usually comes with necessary unassembled components that require assembly. Components like stepper motors, linear motor systems, spindle or router motors, controllers, wiring harnesses, power supply, nuts, bolts, and brackets can be included in the kit. Usually, the manufacturer provides a user manual that helps the operator build the machine properly.

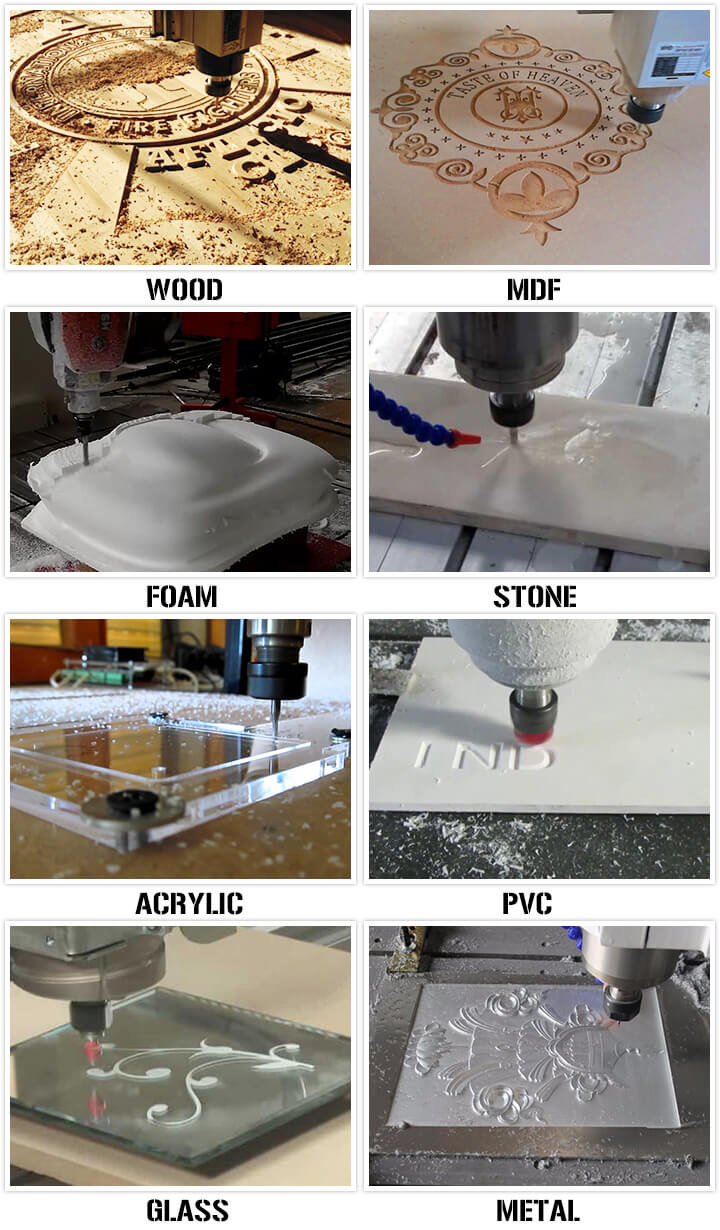

This kit offers a wide range of usability with several materials such as wood, plastics, acrylics, foams, composites, and soft metals like aluminum.

2×4 Benchtop CNC Router Kit Features

⇲ High-quality ball screw and linear guide for X Y Z-axis, stable operation, high precision, and low vibration.

⇲ Taiwan TBI ball screw for Z axis, high precision, smooth transmission.

⇲ Water cooling spindle with high quality, high precision, and less noise.

⇲ Fuling inverter with more stable performance.

⇲ Mach3 control system with humanized design, DSP offline for option.

⇲ Auto tool setting, helping to set the tools, and not break the tools.

⇲ Power off and break point, continuing processing.

⇲ Good software compatibility: Type3, Artcam, Ucancam. All kinds of CAD/CAM software.

⇲ Manual Lubrication system of all machines, just one press, easy to operate.

⇲ High-speed moving gantry.

⇲ Cast iron structure for high precision.

Advantages of Benchtop Models

Benchtop models offer several advantages. Due to their compact size, they can be set up on a workbench or table. This saves space and makes them ideal for small businesses and industries. The 2-foot by 4-foot router kits are extremely popular. It has a bed size of only 2 feet by 4 feet yet holds the material and gets the job done with precision and accuracy.

Besides, these models are popular because,

✔ Comparing larger industrial CNC routers they offer better portability. The lightweight makes it easier to move from one place to another.

✔ Benchtop models offer easier installation and setup comparing larger CNC machines. They often come with a proper instruction manual and necessary components with the kit. So, it becomes easy and smooth for the operator to set up the router simply within a shorter space.

✔ These are more cost-effective and affordable than some big routers. DIY kit availability makes them more popular among small businesses.

✔ Even though a benchtop CNC router has less workspace it offers a wide range of materials and applications. These models do versatile performances with a good reputation.

✔ The User-friendly interface of the router helps even a newbie to learn and operate the machine in a short time.

Technical Parameters of Benchtop CNC Router Kit with 2×4 Table Size

| Model | STG6012 |

| Table Size | 600x1200x200mm |

| Spindle Type | Water cooling spindle |

| Spindle Power | 2.2KW/3.0KW |

| Spindle Rotating Speed | 0-24000rpm |

| Worktable | T-slot table/Vacuum table |

| Locating Precision | |

| Operating Temperature | 5°C-40°C |

| Working Humidity | 30% – 75% (Without condensed water) |

| Working Precision | ±0.03mm |

| System Resolution | ±0.001mm |

| Control Configuration | Mach3/DSP |

| Data Transfer Interface | USB/PC |

| System Environment | Windows |

| Graphic Format Supported | G code: *.u00, * mmg, * plt, *.nc |

| Compatible Software | ARTCAM, UCANCAM, Type3 |

| Cutting Thickness | 0-40mm (Depends on different materials) |

| Power Pupply | AC220±10V, 50 HZ |

| Whole Machine Dimension | 1800*1100*1120mm |

| Net Weight | 250KG |

| Gross Weight | 310KG |

2×4 Benchtop CNC Router Kit Applications

Applicable Industries

Mold making, woodworking, sign making, advertisement, billboard industry, cutting plate production, LED/ neon light through, literally shaped hole cut, stone processing, crafts manufacturing, light box cutting, building model cutting, indoor decoration, light equipment mold processing, acrylic board processing, metal fabrication and so on.

Applicable Materials

Wood, MDF, plywood, PVC, rubber, ABS plate, acrylic, double color sheet, organic glass, ACP, plastic, aluminum, copper, brass and other soft metals.

2×4 Benchtop CNC Router Kit Projects

2×4 CNC Router Table Package

We adopts plywood package case (veneer wood case for export) to leave the CNC router machine in good condition.

Benchtop CNC Router Service

✔ 24/7 technical support by Live Chat, Remote Desktop, Email or Calling.

✔ English manual and CD video for CNC router machine operation and maintenance.

✔ Hardware: One year on all parts (without personal damage).

✔ Software: Whole life on update for free.

✔ Maintenance and technological support: Whole life.

✔ Our engineers are available to service machinery overseas.

Considering Factors

A CNC router kit is usually a good deal due to its functionality and versatility. Buying a benchtop CNC router model, specifically with a 2×4 table size can be more cost-effective and efficient. Follow a few key factors pointed out by our expert for any purchase of a benchtop or tabletop CNC router.

⇲ Check the resolution, repeatability, and accuracy rate provided by the manufacturer.

⇲ User reviews and testimonials can provide real-life performance data.

⇲ Ensure the compatibility of the material you will use.

⇲ Consider spindle speed, feed rates, and acceleration capabilities which can significantly impact the production rate and efficiency of the router.

⇲ Proper information on assembling and support materials is equally valuable in terms of a good benchtop CNC router machine.

⇲ Good software support and customer support are some signs that you are making the right purchase. Research that.

⇲ Manufacturers that offer reliable customer support and warranty are most likely to deliver an effective product to your doorstep.

⇲ Considering the budget try to buy the model that features upgradability and expansion options.