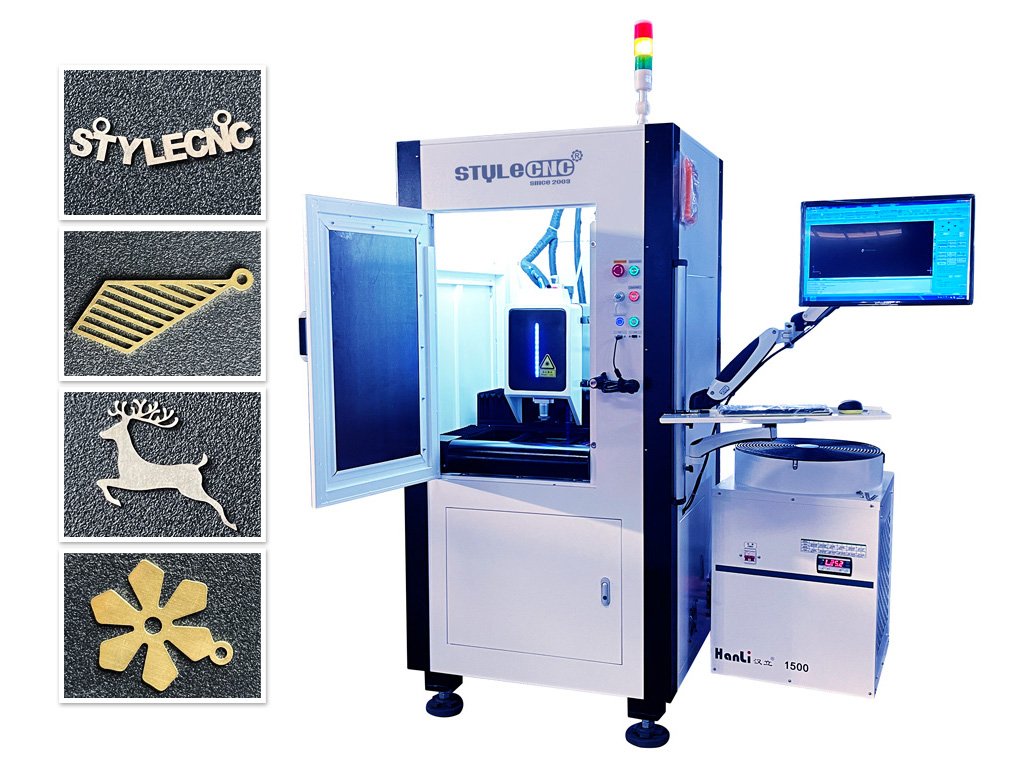

Mini Laser Metal Jewelry Cutter for Silver, Gold, Copper

It takes more than skill to make beautiful metal jewelry. You need accuracy and finesse. That’s where the ST-FC3030 small laser jewelry cutter comes in.

The ST-FC3030 produces unparalleled results, with a level of detail that exceeds expectations. It is compatible with more than simply silver and gold. For example, you can readily deal with copper or stainless steel.

If you want to manufacture unique metal jewelry, you just need one machine – STYLECNC’s ST-FC3030.

- What Is Metal Jewelry?

- What Is Laser Metal Jewelry Cutter?

- How Does It Work?

- Why Choose Precision Laser Cutter to Cut Metal Jewelry of Silver, Gold, Copper? - Pros & Advantages

- Specifications

- Features

- Applications

- Buying Consideration

- Maintenance and Tips!

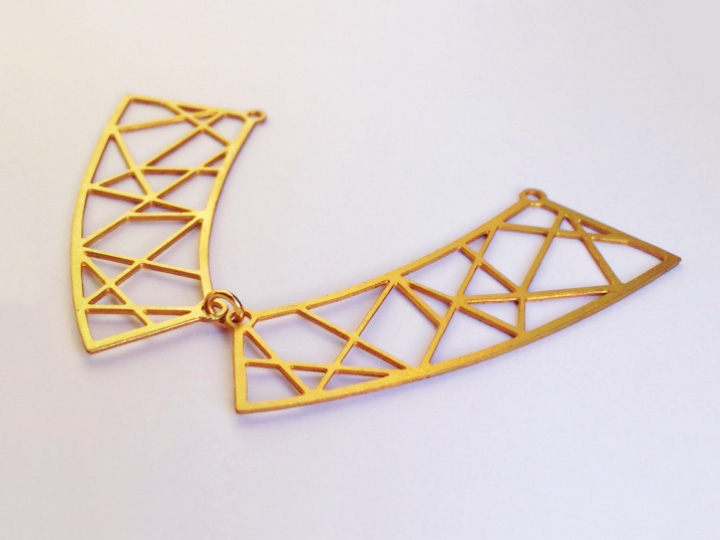

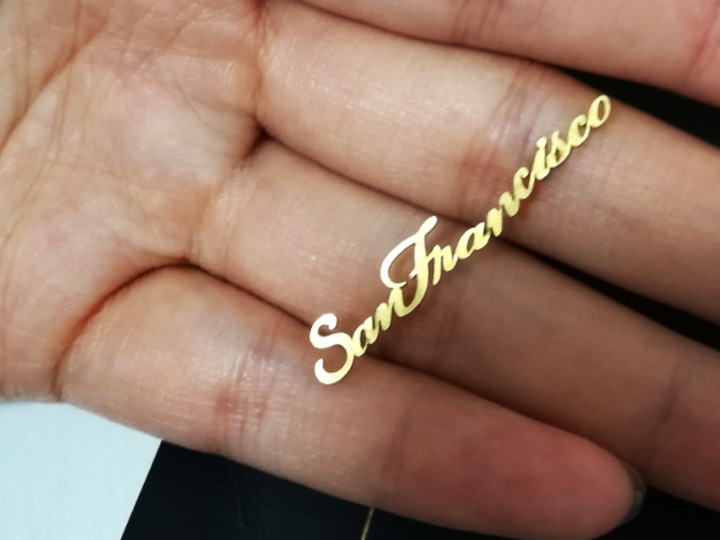

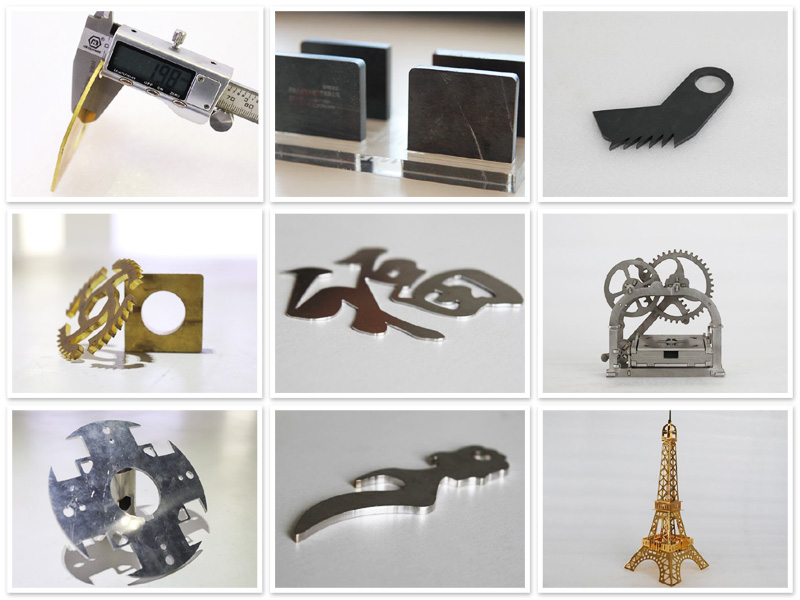

- Precision Laser Cutting Metal Jewelry Projects of Silver, Gold, Copper, Stainless Steel

- Warranty and After-Sale Service

What Is Metal Jewelry?

Metal jewelry refers to rings, earrings, necklaces, bracelets, brooches, pendants, cufflinks, and other personal ornaments made of gold, silver, copper, colored stainless steel, and some precious metal materials.

Most metal jewelry is made of precious metals with small sizes, which requires higher cutting precision with a low loss rate. Traditional mechanical cutting can no longer meet the needs of metal jewelry making. Laser cutting will be the best cutting tool for metal jewelry manufacturing due to its fast speed, high precision, good quality, environmental protection, and non-destructive cutting. The metals used to make jewelry are different in terms of softness, hardness, and reflective properties, which makes fiber lasers the best laser source for precise cutting metal jewelry.

What Is Laser Metal Jewelry Cutter?

A laser metal jewelry cutter is a type of automatic fiber laser metal cutting tool kit used to precise cut silver, gold, stainless steel, copper, titanium, and some precious metals to make earrings, rings, necklaces, brooches, bracelets, cufflinks, pendants and other personal ornaments.

It is a modern tool that uses laser technology to cut, engrave, and shape metal pieces used in jewelry making. Laser cutters can work with various metals making them ideal for creating intricate designs and personalized pieces.

A laser metal jewelry cutter is combined with complicated parts that include the laser source, optical system, control system, work surface, cooling system, and some additional accessories. The most commonly used types include CO2 lasers and fiber lasers.

How Does It Work?

Laser metal jewelry cutters operate based on laser technology principles. Material interaction is also very important. A Laser metal jewelry cutter does the job in several steps starting with the input of the design. Below the process is mentioned step by step.

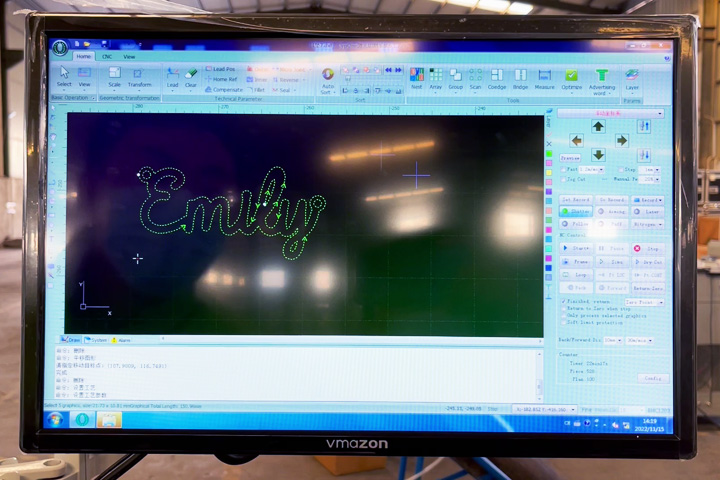

⇲ Design Input: The design created by CAD software uses CAM software to change into machine-readable format.

⇲ Laser Generation: CO2 or fiber laser generates high-temperature concentrated light.

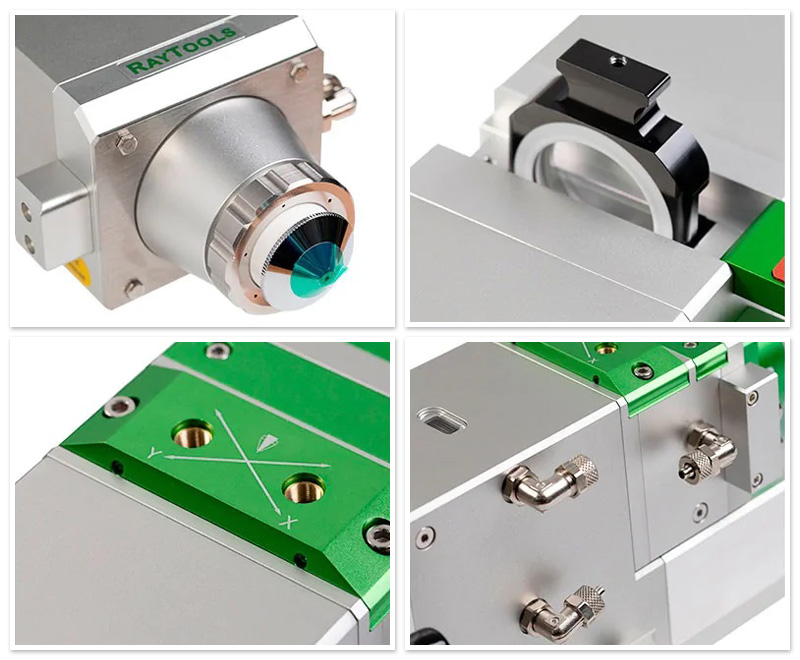

⇲ Beam Focusing: The optical system focuses the high-temperature beam on the fixed point of the surface of the metal to cut or engrave.

⇲ Material Interaction: The heat of the laser beam varies for different metals.

⇲ Controlled Movement: The laser moves following the design pattern made with software.

⇲ Cooling: A proper cooling system is crucial to retain the original shape of the products.

⇲ Removal of Residue: Once done with the production, clean and give a finishing touch.

Why Choose Precision Laser Cutter to Cut Metal Jewelry of Silver, Gold, Copper? – Pros & Advantages

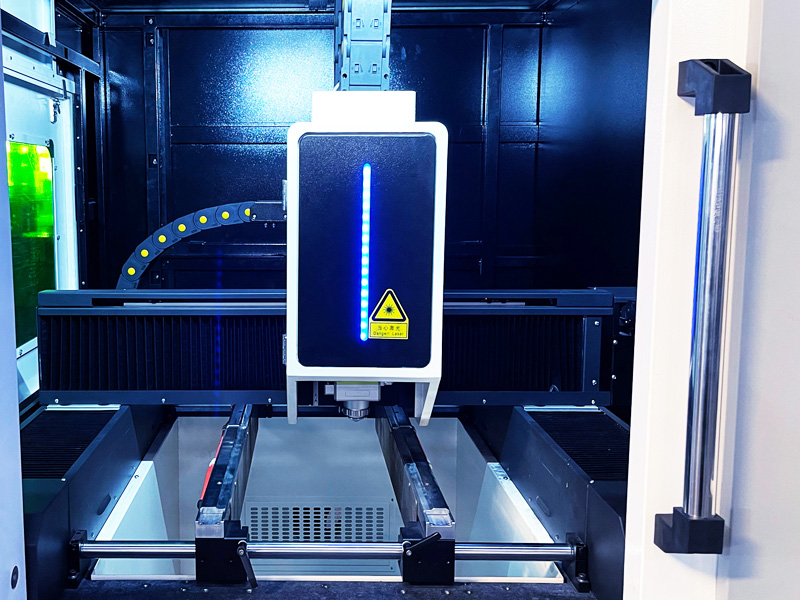

✔ Compact design with CE standard anti-radiation glass, more safer in metal cutting.

✔ High precision fiber laser cutting machine adopts imported Japan AC servo drive system, fast cutting.

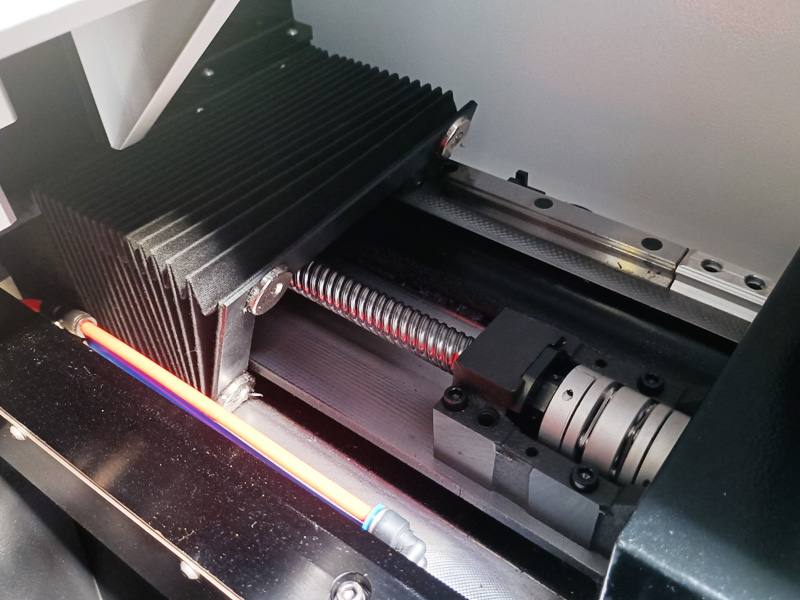

✔ Y axis equipped with high-accuracy ball-screw transmission to ensure the straightness in high-speed cutting.

✔ Durable and not easy to deform.

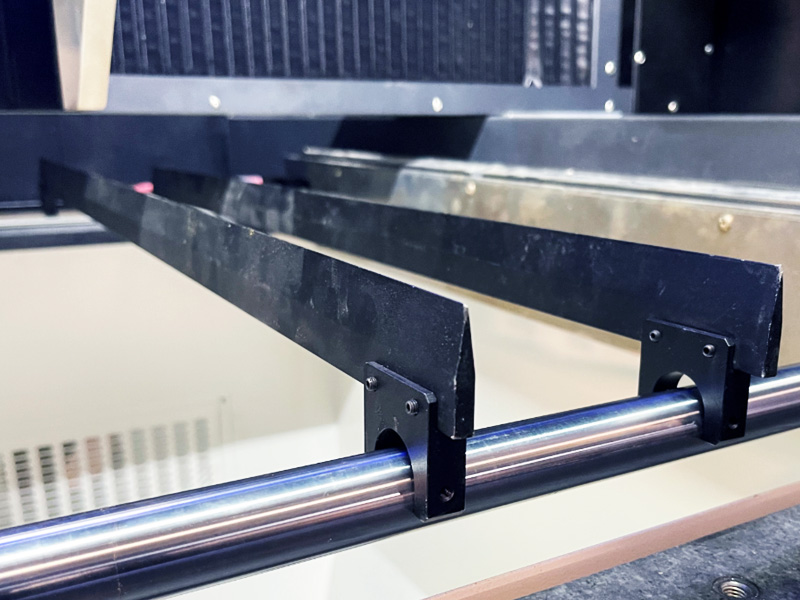

✔ Pneumatic clamps combined with a movable blade table, make the position more accurate, pneumatic clamps to fix the thin materials, and blade table for thicker metal.

✔ Fully enclosed shield protection, prevents the precious metals debris from being discharged during cutting.

✔ Collect tray under the table helps to collect the debris quickly.

Specifications

| Machine Model | ST-FC3030 |

| Max. Working Area | 300mm x 300mm |

| Laser Source | JPT Brand |

| Laser Wavelength | 1080nm |

| Repeated Positioning Precision | ±0.03mm |

| Max. Running Speed | 40m/min |

| Max. Acceleration | 0.5G |

| Driving Mode | High Precision Ball Screw Drive |

| Voltage | 220V/50HZ/60HZ |

Features

JPT laser source

High-performance laser source with resist high-reflection features that make the best cutting effect.

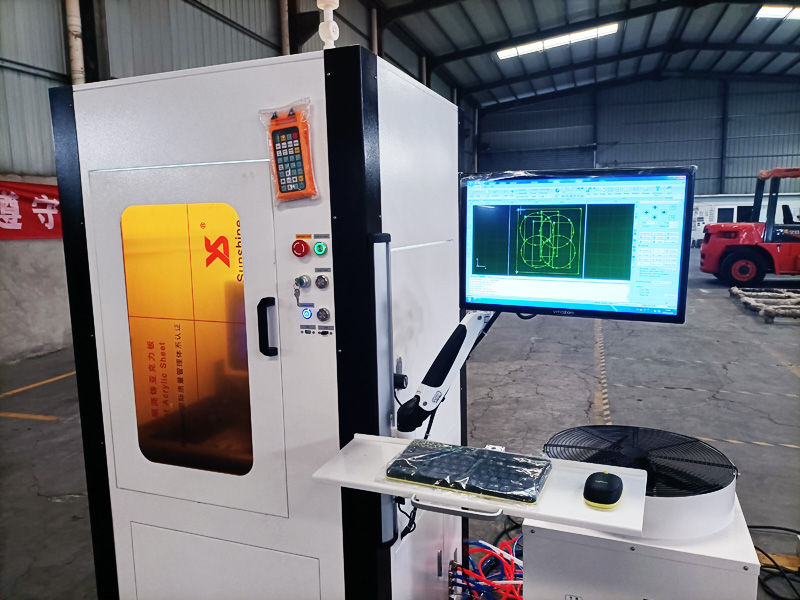

Cypcut control system with Cypone software

The software with English language, supports DXF, PLT, AI, and NC file format.

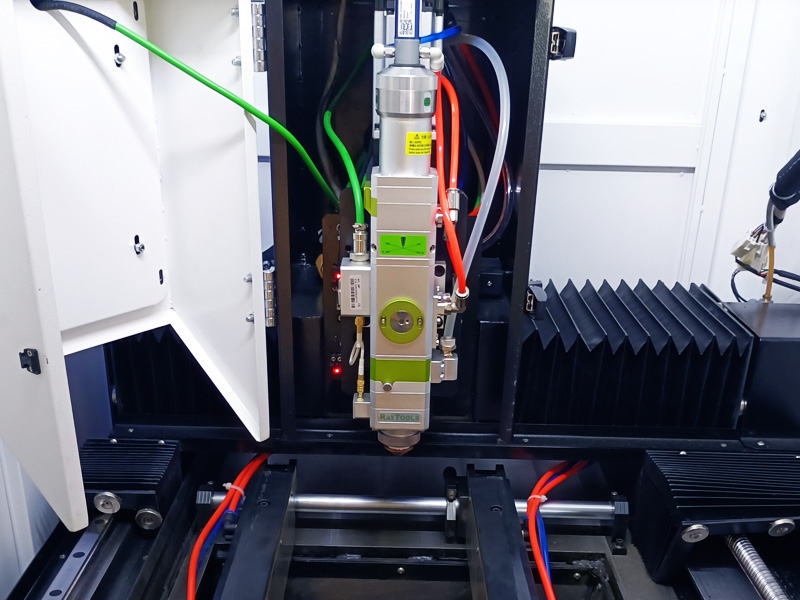

Swiss Raytools brand laser cutting head

To ensure a smooth cutting surface without burrs.

The auto-focus head can be a good option.

Dual control water chiller

To cool the laser source and cutting head in long time use.

Dual cooling function.

Real-time alarm.

Machine protection.

Industrial computer with PC screen arm

Easy to use.

Powerful functions.

Complete the cutting process and debugging easily.

Real-time alarm, stable and reliable.

High-definition pad display with remote controller

The controller can remotely control the laser working within 10m.

Ballscrew transmission

Double Taiwan TBI grinding ball-screw transmission on the Y axis, high precision, and fast speed.

Japanese servo driving system

Match with the ball-screw transmission system, improving cutting speed and precision.

Automatic pneumatic clamp system

It can automatically clamp the metal strip for cutting.

Movable blade table

When cutting thicker metal that can’t be fixed by the clamp table, the blade table can be equipped.

Applications

Mini laser metal jewelry cutters are versatile tools. They are highly used in the metal jewelry industry for cutting and shaping, engraving and marking, creating custom jewelry designs, inlay works, surface texturing, prototyping and small-scale production, repair and restoration of metal jewelry, etc.

Laser jewelry cutter is mostly used in the metal jewelry industry, such as rings, earrings, necklaces, bracelets, brooches, pendants, cufflinks, and other personal ornaments made of stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating zinc plate, gold, silver, copper, colored stainless steel and some precious metals.

These machines are highly appreciated for their wide range of applications and versatility.

Buying Consideration

Buying a laser cutting machine is an asset in the jewelry industry. The right choice can provide value for a long time in business. Several factors can help finding the right machine for your business model. Let’s take a look at the key factors you must follow while buying your metal jewelry cutter.

✔ Laser type and Power

CO2 and fiber lasers are the most commonly used types. CO2 features more versatility with materials and fiber laser features efficient cutting.

The power of the laser determines the cutting ability. In jewelry making 20-50 watts is typically sufficient.

✔ Precision and Accuracy

Choose a machine that provides higher precision quality. Check the tolerance levels usually indicated in micrometers.

✔ Work Area Size

Ensure a large work-bed cutter for more production but also consider the workspace area.

✔ Software Compatibility

The laser cutter should support the latest design software like AutoCAD, Adobe Illustrator, etc. A few models come with their proprietary software.

✔ Build Quality and Durability

A robust frame and high-quality materials will ensure the longevity and consistent performance of your machine.

✔ Ease of Use

Choose a machine that comes with a user-friendly control system. Especially if you are a beginner, clear instructions and intuitive controls are a must.

✔ Safety Features

Protective enclosures, emergency stop buttons, and safety interlocks are some crucial safety features to ensure firsthand.

✔ Customer Support and Warranty

Check the manufacturer’s reputation for customer service and the terms of the warranty.

✔ Cost and Budget

Budget plays a vital role. Therefore, take a tour of the models available within your budget. It is highly suggested not to compromise the quality if willing to grab a good deal.

Maintenance and Tips!

Like any other machine, your laser cutter also requires regular maintenance. A routine checkup and maintenance will ensure the optimal performance and longevity of the machine.

Our experts have given some basic and pro tips to treat your metal jewelry laser cutter effectively.

⇲ Regularly clean laser lenses and mirrors. Do not forget to clean the work area as well.

⇲ Periodically check the calibration and alignment of the laser beam.

⇲ Check the coolant levels and replace the coolant as needed. Clean the cooling fans and vents to ensure proper airflow.

⇲ Follow the manufacturer’s recommendations for lubrication intervals and the type of lubricant to use. Avoid regular lubrication and solutions.

⇲ Keep the control software up to date to benefit from the latest features.

⇲ Regularly inspect cables, connectors, and switches for signs of wear or damage.

⇲ Schedule regular professional servicing.

Precision Laser Cutting Metal Jewelry Projects of Silver, Gold, Copper, Stainless Steel

Laser Cut Metal Jewelry Projects.

Laser Cut Gold Jewelry Projects.

Laser Cut Copper Jewelry Projects.

Laser Cut Silver Jewelry Projects.

Laser Cut Stainless Steel Jewelry Projects.

Laser Precision Cut Metal Projects.

Warranty and After-Sale Service

• 3-year limited warranty for the fiber laser source and main components without consumable parts.

• Staffed by experienced service professionals, our support center is never closed. We field more than 10,000 requests each year, resolving 95% with just online support.

• Our technical support experts are available 24 hours a day, 365 days a year.