Sale of Special Machine ROLLER 2800 – for Rolling Material

We offer for sale a special machine ROLLER 2800, it is designed for efficient rolling of cylindrical, conical and transitional radius surfaces of shaft components, especially vehicle axles.

Manufacturer Kovosvit MAS

Year of manufacture 2018

Circulating diameter without using B-axis tilting: 300 mm

Max. rolling force without tilting of axis B: 50 kN

Max. workpiece weight: 1,000 kg

Power S1: 11 kW

Cold forming technology – Material strengthening by means of rolling

In today’s modern industry, technological innovation is a key element of efficient production. One of these innovative methods is cold rolling technology, especially in conjunction with a highly specialized machine such as the MASTURN 70/3000 cnc . This technology has found application especially in the production of shaft components for vehicle axles, where the key is to achieve specific shapes and surface treatments.

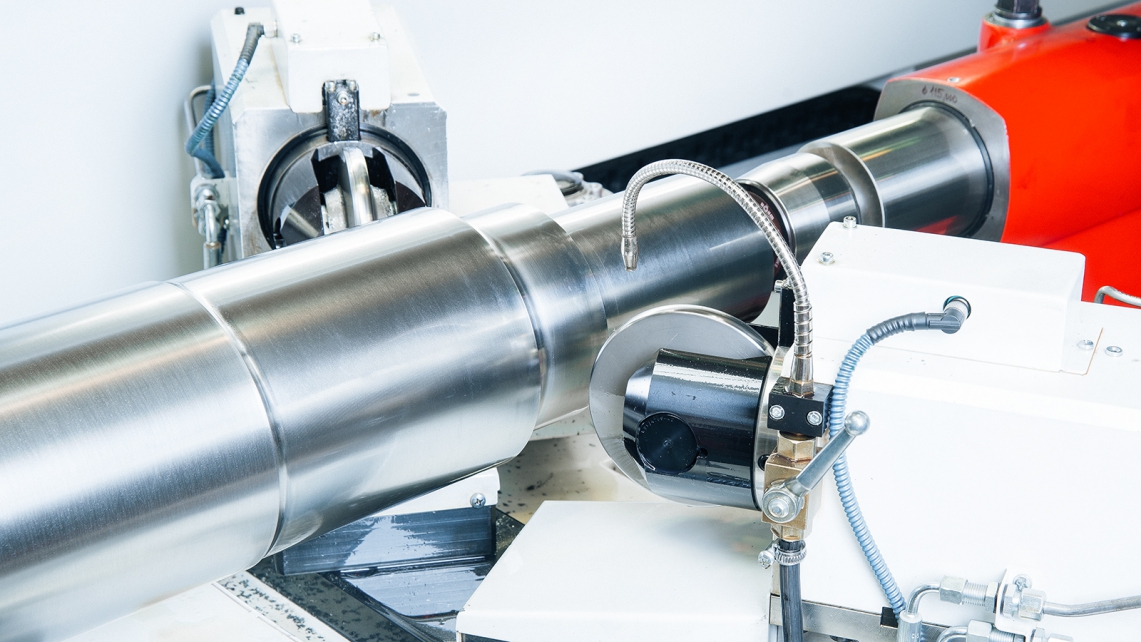

Principle of operation of the machine

The special MASTURN 70/3000 CNC machine is built on the foundations of a classic turning machine and is used for surface rolling technology. The machine has a rolling device located on a longitudinal support, which moves along the machine bed using the CNC-controlled Z axis. Movement in the X axis is realized by the quills of the rolling heads, which are equipped with their own rolling tools, driven by a hydraulic system.

Hydraulic system and safety features

The hydraulic unit equipped as standard with the machine enables continuous changes in pressure and force during rolling in a defined range of pressures. The tailstock with a hydraulically controlled quill is additionally equipped with a special mechanical locking device, which ensures the safe transfer of axial forces. The spindle of the machine is placed on a reinforced centering pin, which contributes to the overall stability of the device.

Oil management and system integration

A separate oil management, including a tank and a tub under the working area of the machine, ensures optimal lubrication and cooling during operation. The entire roller support system is integrated into the covered area of the machine, which increases safety and minimizes the risk of dirt in the work area. The sliding guide surfaces of the additional roller support are connected to the central lubrication system of the machine, which ensures a long service life and reliability.

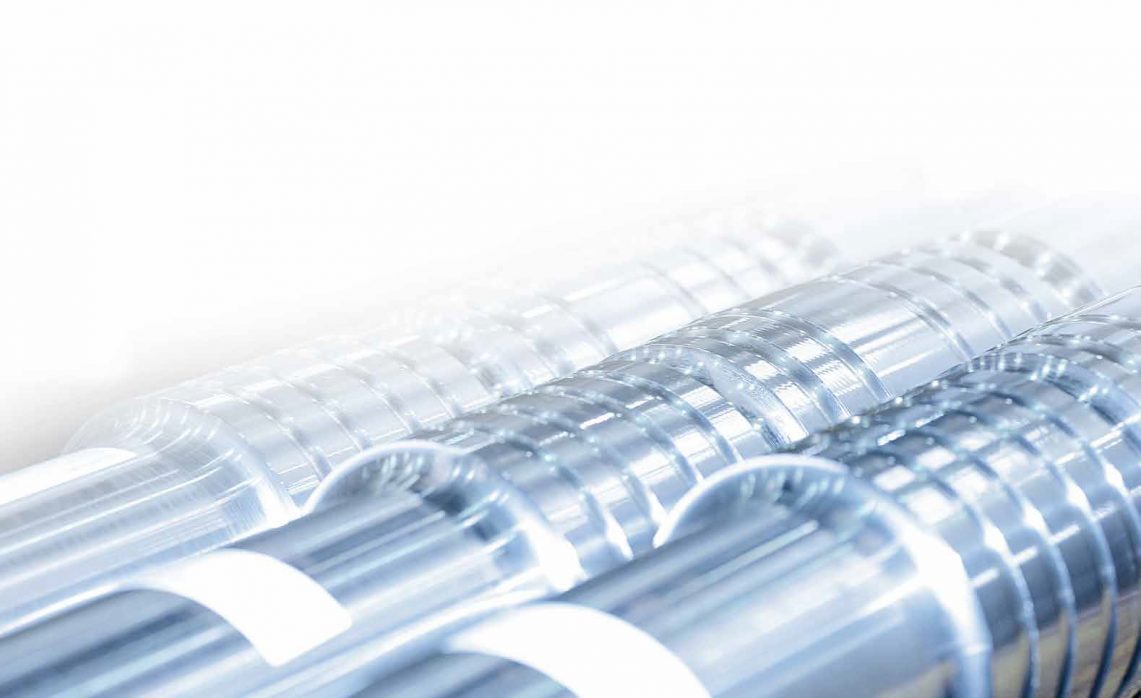

Advantages of a rolled surface

The main advantage of cold rolling technology is the achievement of a smooth surface of the components without the need for precise grinding. This method replaces grinding, but with a significant reduction in costs. Rolling is ideal for strengthening surfaces with non-tolerated dimensions or as a preparation before grinding to a tolerated dimension.

The resulting rolled surface offers material savings of up to 8%, higher fatigue fracture resistance, increased hardness, a smooth surface with high resistance to abrasion and corrosion. This technology also enables an ecological approach by replacing molybdenum injection with surface rolling.

In today’s era, when efficiency, quality and environmental friendliness are emphasized, cold rolling technology is becoming an invaluable tool in the field of industrial production.

Basic concept:

- Cold forming technology – strengthening of the material

- Special machine, the skeleton of the machine is derived from the standard turning machine MASTURN 70/3000 CNC.

- The function of the machine consists in the technology of rolling cylindrical, conical and transitional radius surfaces of shaft components, e.g. vehicle axles.

- The use of the machine for the specialized production of components using surface rolling technology.

- The rolling device is located on a longitudinal support.

- The support moves using the CNC-controlled Z axis along the machine bed in the longitudinal direction.

- The movement in the X axis is realized by the quills of the roller heads, into which the own roller tools are clamped.

- The movement of the quills and the rolling force is derived hydraulically.

- As standard, the machine is equipped with a hydraulic aggregate.

- Continuous changes in pressure and force on rolling tools during the work cycle in a defined range of pressures.

- Display of current roller force, recording and archiving.

- The tailstock with a hydraulically controlled quill is equipped with a special mechanical locking device for the safe transmission of axial forces

- The spindle of the machine is placed on a bed on a reinforced centering pin.

- Separate oil management including tank and tub under the working area of the machine.

- The entire roller support system is integrated into the covered space of the machine.

- The sliding guide surfaces of the additional roller support are connected to the machine’s central lubrication system .

- The machine can be operated in both manual and automatic cycles.

The advantages of rolled surfacing are to achieve a smooth part surface by cold forming the surface layer. It replaces grinding technology with the quality of processing, but without the precision of the size of the processed surface as with grinding. Rolling is suitable as a finishing operation for strengthening surfaces of non-tolerated dimensions or as a technology for strengthening the surface layer before final grinding of surfaces to a tolerated dimension.

Rolling is used primarily for the reasons of material savings of up to 8%, as well as higher resistance to fatigue fracture, i.e. higher fatigue strength in cyclic stressing of the component, increased hardness and a very smooth surface, ensures higher resistance to abrasion and corrosion, another considerable advantage for environment is the possibility to replace molybdenum injection by rolling the surface.

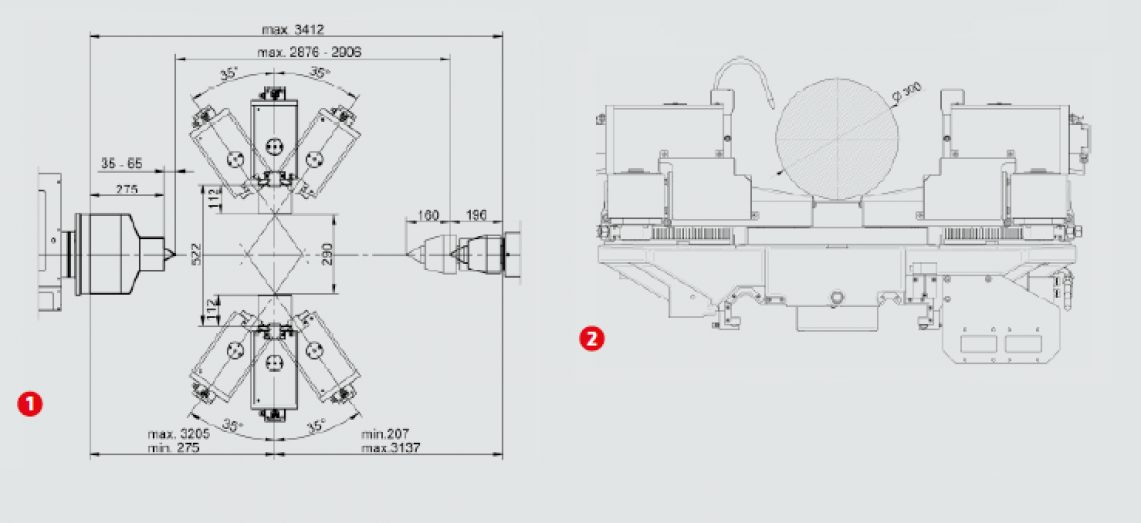

Workspace

- The working space of the machine, where the distances and dimensions are indicated in the first place, as regards the clamping of the shaft, i.e. spindle clamp, distance of the face of the clamp from the front surface of the spindle 275mm, the start of the machine tailstock (referred to the distance of the inserted tailstock quill from the face of the machine spindle, i.e. 3412mm, the size of the quill extension 160mm and the distance of the tip of the rotating tip (in our case, Röhm MK6 tip VEL.116 – Id.Nr.093439) from the face of the tailstock quill 192mm. The total distance between the points is then 2876-2906mm depending on the shape and size of the centering hole of the axle. Furthermore, in the working area, the start-up of the support with roller rolls is indicated in the working area with the distances just to the face of the spindle and the face inserted tailstock quills, the angular swing of the roller quills (±35 degrees), the position of the center around which tilting takes place, i.e. 290mm and the value of the distance between the faces of the inserted quills of the roller heads 522mm and the extension of each of the quills 112mm are indicated. Most of the dimensions are determined for the spindle face, to the face of the tailstock quill and to the faces of the quills of the roller heads, because the spindle holder itself, the tailstock tip and the rolling tools are selected and constructed specifically according to the customer’s request and their values may vary.

- The maximum rotating diameter of the part without tilting the roller heads.