What Does A CNC Machinist Do?

What Does A CNC Machinist Do?

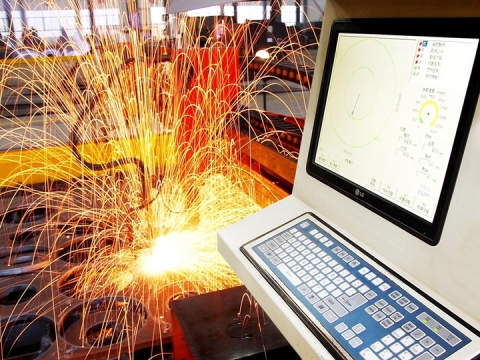

CNC (Computer Numerical Control) machining is a precision and efficient method of manufacturing in the modern day. The production of complex parts and components has been completely transformed by CNC machining, which is used to create everything from precise medical implants to complex aircraft components.

Meanwhile, the CNC machinists who are the backbone of this technological advancement play the most intriguing role in the sector. A CNC machinist is now the key feature of industry manufacturing.

Come along as we set out to discover the fundamentals of CNC machining, including its definition, application in modern industry, and internal mechanisms. And top of that we will embark on a journey to uncover the job and the techniques of a CNC machinist.

Definition of CNC Machining

At its core, CNC machining is a subtractive manufacturing process where computer-controlled machines precisely remove material from a workpiece to create a desired shape. Unlike traditional manual machining, which relies on human operators to guide cutting tools, CNC machining automates this process through the use of programmed commands. These commands, typically written in G-code, dictate the movements and actions of the machine’s cutting tools with exceptional accuracy and repeatability.

Importance of CNC Machining

CNC machining has become a part and parcel of our daily life. The automated manufactured products we use in everyday life are one way or another come through a CNC machining system. This technology is widely being used for efficient and repeatable production of goods.

From automotive to aerospace, electronics to medical components, with numerous metals and materials CNC machining has been playing a crucial role.

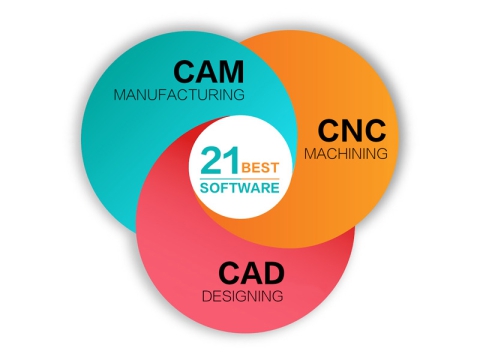

The abilities of CNC tech create its value over time. Following CAD/CAM software and sophisticated techniques, CNC machining can offer précised and consistent production which is very important for any industry.

The role of CNC machinists

CNC machinists are the foundation of precision production. They use their knowledge and skills to accurately and precisely transform raw materials into complex components. Let us examine the many facets of CNC machinists’ roles, from their routine duties to their vital functions in the production process.

What CNC Machinists Do

Programming, configuring, and running CNC machines to create precision parts and components is the responsibility of these highly trained specialists. Their duties cover a broad spectrum of activities, such as:

✔ Programming

CNC programmers use specialized software to develop and edit CNC programs that specify the tool paths, cutting parameters, and other instructions needed to build a specific part.

✔ Setup

Before starting the machine for production a machinist must prepare the CNC machine by installing appropriate cutting tools and securing the item on the bed.

✔ Operation

Once the machine is set up the machinist monitors the performance and sets the necessary parameters accordingly. This ensures the quality and accuracy of the final products.

✔ Quality Control

CNC machinists are responsible for the quality of the final products. They are to inspect the products using precision measuring instruments like micrometers, calipers, and gauges.

✔ Maintenance

Besides the production duties, they have responsibility for the maintenance of the CNC machines. Routine maintenance tasks such as cleaning, lubricating, and replacing damaged parts TO ENSURe the longevity of the machines are also done by the CNC machinists.

Importance of CNC Machinists in the Manufacturing Process

Perhaps a CNC machinist plays the most vital role in the manufacturing process. A skilled CNC machinist can turn a spoiled part into a good production. Their expertise ensures that parts are produced with utmost precision and consistency.

The absence of a skilled machinist will lead to the quality compromise of your product and manufacturing errors resulting in less profit in your business. Their ability to troubleshoot mechanical issues, and optimize machining parameters maximize productivity.

Thus it takes so saying that the importance of a CNC machinist in the manufacturing process is very important.

Skills and Qualifications Required to Become a CNC Machinist

This job is not the easiest on the market. A CNC machinist needs to be skilled and have good command over a few things. Becoming a CNC machinist requires a combination of technical skills, practical experience, and specialized training.

Here we have included some of the key skills and qualifications required to become a CNC machinist.

Technical Proficiency

Technical expertise qualifies a machinist. Therefore, a CNC machinist must have an understanding of mechanical principles and machining processes.

Programming Skills

Programming skills are one of the most essential qualities of a CNC machinist. Knowledge of CNC programming languages such as G-Code is necessary to create and edit CNC programs.

Blueprint Reading

The ability to read technical drawings and blueprints is a prerequisite for CNC machinists to comprehend the size and specifications of the items they are shaping.

Attention to Detail

A CNC machinist must give attention to the precision and measurements of the production. A simple miscalculation can cause greater damage. So, minor details should be checked properly by a machinist.

Problem-Solving Abilities

Diagnosing and troubleshooting are common scenarios where an expert CNC machinist can solve problems with skills and expertise.

Training and Certification

Many CNC machinists undergo formal training programs and technical courses. Vocational school or apprenticeships are common among them. To acquire the necessary skills and knowledge, many work out for additional industry certifications.

Programming

CNC programming lies at the heart of the CNC machining process. Machinists can specify the exact movements, tool paths, cutting parameters, and other instructions required to build a specific item by utilizing specialist software to create and modify CNC programs.

G-code (Geometric Code/Gestalt Code) is the specialized programming language for CNC machines. A series of alphanumeric codes represents the commands and parameters. Each code has a different command prompt for the machine.

A CNC machinist can write programming commands with knowledge of G-code. Some examples of programming tasks performed by CNC Machinists are mentioned below.

⇲ Toolpath generation using CAD/CAM software

⇲ Creating workpiece geometry using the machine language

⇲ Setting cutting parameters depending on the type of material and shape

⇲ Implementing tool changes

⇲ Implementing machining strategies

Setup

A proper setup of the machine directly influences the quality, accuracy, and efficiency of the machining process. Only a perfectly aligned, calibrated, and configured CNCN machine ensures the optimal production rate.

This setup is done by a CNC machinist. So, a machinist needs to have proper knowledge of the setup. There are several steps to a complete setup that a machinist must do, such as selecting cutting tools, mounting cutting tools, workpiece fixation, workpiece alignment, setting workpiece zero, calibrating machine parameters, and verifying setup.

Many tools and equipment are attached along with the machine for customized parts production. Equipment like cutting tools, tool holders, work holding devices, measuring instruments, setup blocks and shims, and tool pre-setters need the expertise of a CNC machinist to be utilized.

Operation

In this sector, we will explore and find out the complex relationship between the precision of a CNC machine and the expertise of a CNC machinist. Perhaps, this is the most active part of CNC machining.

Once the setup is complete and the program is loaded the machining process begins with CAD/CAM software command. The final product is achieved through a series of commands. The sequential operations, such as, cutting, routing, milling, turning, drilling, or grinding are the requirements of the parts being manufactured.

Responsibilities of CNC Machinists During Machine Operation

During machine operation, CNC machinists are tasked with a range of responsibilities to ensure the smooth execution of machining operations and the production of high-quality parts. Some of their key responsibilities include:

⇲ Monitoring Machine Performance.

⇲ Maintaining Quality Standards.

⇲ Optimizing Cutting Parameters.

⇲ Implementing Tool Changes.

⇲ Troubleshooting Issues.

Monitoring and adjusting machine parameters for optimal performance is another important task for a CNC machinist. Keen attention to detail and a thorough understanding of machining principles are required to achieve that goal.

Real-time monitoring, data analysis, dynamic adjustments, tool wear compensation, coolant, and lubrication management are the responsibilities of a CNC machinist to operate with utmost care and expertise.

Quality Control

Quality control is the cornerstone of CNC machining, ensuring that every part produced meets the stringent standards of accuracy, consistency, and reliability demanded by industries. In CNC machining, where tolerances can be measured in microns and deviations can have significant ramifications, quality control is paramount.

Several methods and tools are used to inspect the quality of the final products. Some of the common tools and methods are:

⇲ Coordinate Measuring Machines (CMMs).

⇲ Surface Finish Analysis.

⇲ Visual Inspection.

⇲ Non-Destructive Testing (NDT).

⇲ Dimensional Inspection.

Role of CNC Machinists in Ensuring Quality and Precision

The quality and precision mostly come from the command input which is given by the operator. A CNC machinist here plays a major role in ensuring the specifications, CAD models, and blueprints are accurately given.

Implementing quality control procedures is another task done by the machinist. A CNC machinist inspects the parts with precise measuring tools to find out any defects. Besides, he adjusts the machine parameters such as cutting speed, feed rate, tool path, etc. to optimize the performance.

When there is a bug or problem a CNC machinist identifies and solves it addressing well. He is always looking for improvement in the production.

Maintenance

Maintaining a CNC machine is a great way to cover up your cost. It is crucial to take good care of the machine for a longer lifespan. Moreover, good maintenance will increase profitability and offer a long service time.

Let’s explore the critical importance of maintenance for a CNC machine and the importance of a CNC machinist who is bound to take care of it.

To prevent premature wear, breakdown, and costly repair regular maintenance is a must. Performing a regular maintenance checkup a machinist can identify any issues before they escalate.

Several tasks include the routine maintenance task of a CNC machinist. The common ones are:

⇲ Cleaning.

⇲ Lubricating.

⇲ Checking fluid level.

⇲ Inspecting machine components.

⇲ Calibrating machine parameters.

⇲ Performing preventive maintenance.

Final Words

As we come to the end of our investigation into CNC machining and the critical importance and role of CNC machinists, let us take a moment to consider and recognize their technical proficiency, and consider their invaluable contributions.

Their mastery of CNC programming, setup, operation, maintenance, and quality control is a testament to their dedication to excellence and their relentless pursuit of perfection.

CNC machinists will be leading the way in incorporating smart production systems, applying cutting-edge machining methods, and adopting innovative manufacturing strategies in the upcoming years. Their capacity for flexibility, inventiveness, and problem-solving will be crucial for negotiating the intricacies of the digital era and seizing fresh chances for advancement and expansion.