What Is CNC (Computer Numerical Control)?

What Is CNC (Computer Numerical Control)? – User Guide

Concept

NC (Numerical Control)

NC is a technology that uses digital signals to automatically control objects (such as the motion of the machine tool and its working process), referred to as numerical control.

NC Technology

NC technology refers to the automatic control technology that uses numbers, letters and symbols to program a certain working process.

NC System

NC system refers to the organic integrated system of software and hardware modules that realize the functions of NC technology. It is the carrier of NC technology.

CNC System (Computer Numerical Control System)

CNC (Computer Numerical Control) system refers to the numerical control system with computer as the core.

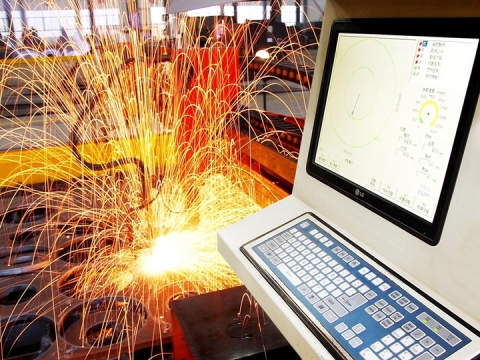

CNC Machines

CNC machine refers to a machine tool that uses Computerized Numerical Control technology to control the machining process, or a machine tool equipped with a Computerized Numerical Control system.

NC Definition

Numerical Control is the full form of NC for machine tools. Numerical Control (NC) enables an operator to communicate with machine tools through numbers and symbols.

CNC Definition

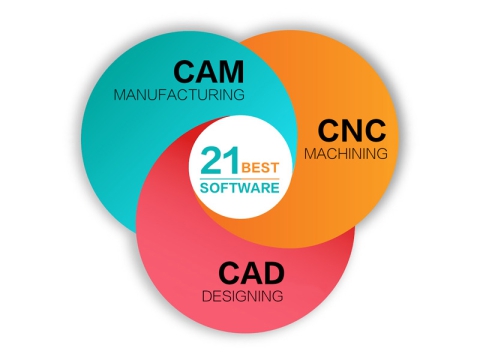

CNC is the short name of Computer Numerical Control, which is an automatic technology of controlling machine tools to complete automated machining with CAD/CAM software in modern manufacturing process. New machine tools with CNC have enabled industry to consistently produce parts to accuracies undreamed of only a few years ago. The same part can be reproduced to the same degree of accuracy any number of times if the program has been properly prepared and the computer properly programmed. The operating G-code commands which control the machine tool are executed automatically with high speed, accuracy, efficiency, and repeatability.

CNC machining is a computerized manufacturing process, the machine is connected to a computer, the computer will tell it where to move. First, the operator should do the toolpath creation, the operator uses a software program to draw the shapes and create the tool path that the machine will follow.

The ever-increasing use in industry has created a need for personnel who are knowledgeable about and capable of preparing the programs which guide the machine tools to produce parts to the required shape and accuracy. With this in mind, the authors have prepared this textbook to take the mystery out of CNC – to put it into a logical sequence and express it in simple language that everyone can understand. The preparation of a program is explained in a logical step-by-step procedure, with practical examples to guide the user.

Component

CNC technology consists of three parts: bed frame, system and peripheral technology.

The frame kit is mainly composed of basic parts such as bed, column, guide rail, working table and other supporting parts such as tool holder and tool magazine.

The numerical control system is composed of input/output equipment, computer numerical control device, Programmable Logic Control (PLC), spindle servo drive device, feed servo drive device and measuring device. Among them, the device is the core of the numerical control system.

Peripheral technology mainly includes tool technology (tool system), programming technology, and management technology.

Glossary

CNC: Computer Numerical Control.

G-Code: A universal numerical control (NC) machine tool language that specifies axis points to which the machine will move.

CAD: Computer Aided Design.

CAM: Computer Aided Manufacturing.

Grid: The minimum movement, or feed of the spindle. The spindle automatically moves to next grid position when button is toggled in continuous or step mode.

PLT (HPGL): Standard language for printing vector-based line drawings, supported by CAD files.

Toolpath: User-defined, coded route which the cutter follows to machine the workpiece. A “pocket” toolpath cuts the surface of the workpiece; a “profile” or “contour” toolpath cuts completely through to separate the workpiece shape.

Step Down: Distance in Z-axis that the cutting tool plunges into the material.

Step Over: Maximum distance in X or Y axis that cutting tool will engage with uncut material.

Stepper Motor: A DC motor that moves in discrete steps by receiving signals, or “pulses” in a particular sequence, thus resulting in very precise positioning and speed control.

Spindle Speed: Rotational speed of cutting tool (RPM).

Conventional Cut: Cutter rotates against direction of feed. Results in minimal chatter but can lead to tearout in certain woods.

Subtractive Method: The bit removes material to create shapes. (Opposite of additive method.)

Feed Rate: Speed at which the cutting tool moves through the workpiece.

Home Position (Machine Zero): Machine-designated zero point determined by physical limit switches. (It does not identify actual work origin when processing a workpiece.)

Climb Cut: Cutter rotates with direction of feed. Climb cutting prevents tearout, but can lead to chatter marks with a straight-fluted bit; a spiral-fluted bit will reduce chatter.

Work Origin (Work Zero): The user-designated zero point for the workpiece, from which the head will perform all it’s cutting. X, Y and Z axes are set to zero.

LCD: Liquid Crystal Display (used on the controller).

U Disk: External data storage device that is inserted into a USB interface.

Features

High Accuracy

CNC machines are highly integrated mechatronic products, which are composed of precision machinery and automatic control systems. They have high positioning accuracy and repeat positioning accuracy. The transmission system and the structure have high rigidity and stability to reduce errors. Therefore, Computerized Numerical Control machine has higher machining accuracy, especially the consistency of parts manufacturing in the same batch, and the product quality is stable, the pass rate is high, which is incomparable with ordinary machine tools.

High Efficiency

CNC machines can use a larger amount of cutting, which effectively saves processing time. They also have automatic speed change, automatic tool change and other automatic operation functions, which greatly shorten the auxiliary time, and once a stable processing process is formed, there is no need to perform inter-process inspection and measurement. Therefore, the productivity of Computerized Numerical Control machining is 3-4 times higher than that of ordinary machine tools, or even more.

High Adaptability

CNC machines perform automatic processing according to the program of the processed parts. When the machining object changes, as long as the program is changed, there is no need to use special process equipment such as masters and templates. This is helpful to shorten the production preparation cycle and promote product replacement.

High Machinability

Some mechanical parts formed by complex curves and curved surfaces are difficult to process or even impossible to complete with conventional techniques and manual operations, and can be easily realized by CNC machines using multi-coordinate axes linkage.

High Economic Value

CNC machining centers mostly use process concentration, and one machine is multi-purpose. In the case of one clamping, most parts of the parts can be processed. They can replace several ordinary machine tools. This can not only reduce clamping errors, save auxiliary time between transportation, measurement, and clamping between processes, but also reduce the types of machine tools, save space, and bring higher economic benefits.

Pros & Cons

Pros

Safety

The operator of the CNC machine is safely separated from all sharp parts by a special protective structure. He can still see what’s going on at the machine through the glass, but he doesn’t need to go anywhere near the mill or spindle. The operator also does not have to touch the coolant. Depending on the material, some liquids may be harmful to human skin.

Save Labor Costs

Today, conventional machine tools require constant attention. This means that each worker can only work on one machine. When the CNC era came, things changed dramatically. Most parts take at least half an hour to process each time they are installed. But computer numerical controlled machines do it by cutting the parts themselves. No need to touch anything. The tool moves automatically, and the operator simply checks for errors in the program or settings. Having said that, CNC operators find they have a lot of free time. This time can be used for other machines. So one operator, many machine tools. This means you can save manpower.

Minimum Setting Error

Traditional machine tools rely on the operator’s proficiency with measuring tools, and good workers can ensure parts are assembled with high precision. Many CNC systems use specialized coordinate measurement probes. It is usually mounted on the spindle as a tool and the fixed part is touched with a probe to determine its position. Then, determine the zero point of the coordinate system to minimize the setup error.

Excellent Machine Condition Monitoring

The operator must identify machining faults and cutting tools, and his decisions may not be optimal. Modern CNC machining centers are packed with different sensors. You can monitor torque, temperature, tool life and other factors while machining your workpiece. Based on this information, you can refine the process in real time. For example, you see that the temperature is too high. Higher temperatures mean tool wear, poor metal properties, etc. You can reduce the feed or increase the coolant pressure to fix this. Despite what many say, machining is the most widespread manufacturing method today. Every industry uses machining to some degree.

Stable Accuracy

What’s more stable than a proven computer program? The movement of the instrument is always the same because its accuracy depends only on the accuracy of the stepper motors.

Fewer Test Runs

Traditional machining inevitably has some test parts. The worker has to get used to the technology, he will definitely miss something when doing the first part and testing the new technology. CNC systems have a way to avoid test runs. They employ a visualization system that allows the operator to actually see the inventory after all the tools have passed through.

Easy Machining Complex Surface

Manufacturing complex surfaces with high precision is nearly impossible with conventional machining. It requires a lot of physical labor. CAM systems can automatically form toolpaths for any surface. You don’t have to put in any effort at all. This is one of the greatest advantages of modern CNC machining technology.

Higher Cutting Data

High-speed machining is only possible due to the closed cutting area. At this speed, the chip flies all over the place at high speed. There is a coolant spray after the chips, because when it comes to high-speed machining, the coolant is applied under high pressure. Manual operation is simply not possible when the speed reaches 10000 rpm or more. With high cutting speeds, it is important to keep the feed rate and chip width stable to prevent vibration. It can’t be hard to do it manually.

Higher Flexibility

The traditional method is that milling machines for grooves or flats, lathes for cylinders and tapers, and drilling machines for holes. CNC machining can combine all of the above into one machine tool. Since tool trajectories can be programmed, you can replicate any motion on any machine. So we have milling centers that can make cylindrical parts and lathes that can mill grooves. All of this reduces the set-up of the part.

Cons

High technical requirements for operators and machine maintenance personnel;

Computer numerical control system is not easy to control, not as intuitive as ordinary machine tools;

The purchase cost of the machine tool is more expensive.

Applications

From the perspective of CNC technology and equipment applications in the world, its main application areas are as follows:

Manufacturing Industry

The machinery manufacturing industry is the earliest industry to apply Computerized Numerical Control technology, and it is responsible for providing advanced equipment for various industries of the national economy. The main applications are the development and manufacturing of five-axis vertical machining centers for modern military equipment, five-axis machining centers, large-scale five-axis gantry milling, flexible manufacturing lines for engines, gearboxes, and crankshafts in the automotive industry, and high-speed machining centers, as well as welding, assembly, painting robots, plate laser welding machines and laser cutting machines, high-speed five-coordinate machining centers for machining propellers, engines, generators and turbine blade parts in the aviation, marine and power generation industries, heavy duty turning and milling complex machining center.

Information Industry

In the information industry, from computer to network, mobile communication, telemetry, remote control and other equipment, it is necessary to adopt manufacturing equipment based on super-precision technology and nanotechnology, such as wire bonding machines for chip manufacturing, wafer lithography machines. The control of these equipment needs to use Computerized Numerical Control technology.

Medical Equipment Industry

In the medical industry, many modern medical diagnosis and treatment equipment have adopted numerical control technology, such as CT diagnostic instruments, whole body treatment machines and minimally invasive surgical robots based on visual guidance, orthodontics and dental restoration in stomatology are required.

Military Equipment

Many modern military equipment use servo motion control technology, such as automatic aiming control of artillery, tracking control of radar and automatic tracking control of missiles.

Other Industries

In the light industry, there are printing machinery, textile machinery, packaging machinery and woodworking machinery that use multi-axis servo control. In the building materials industry, there are computer numerical controlled waterjet cutting machines for stone machining, computer numerical controlled glass engraving machines for glass machining, computer numerical controlled sewing machine used for simmons processing and computer numerical controlled embroidery machine used for clothing processing. In the art industry, more and more crafts and artworks will be produced using high performance 5 axis CNC machines.

The application of numerical control technology not only brings revolutionary changes to the traditional manufacturing industry, making the manufacturing industry a symbol of industrialization, but also with the continuous development of numerical control technology and the expansion of application fields, it has played an increasingly important role in national economy and people’s livelihood (e.g. IT and automobile) , light industry, medical treatment, because the digitization of equipment required in these industries has become a major trend in modern manufacturing.

Trends

High Speed / High Precision

High speed and precision are the eternal goals of machine tool development. With the rapid development of science and technology, the speed of replacement of electromechanical products is accelerated, and the requirements for the precision and surface quality of parts processing are also higher and higher. In order to meet the needs of this complex and changeable market, the current machine tools are developing in the direction of high-speed cutting, dry cutting and quasi-dry cutting, and the machining accuracy is constantly improving. In addition, the application of linear motors, electric spindles, ceramic ball bearings, high-speed ball screws and nuts, linear guide rails, and other functional components has also created conditions for the development of high-speed and precision machine tools. The computer numerical control machine tool adopts an electric spindle, which eliminates the links such as belts, pulleys, and gears, which greatly reduces the moment of inertia of the main drive, improves the dynamic response speed and working accuracy of the spindle, and completely solves the problem of vibration and noise when the spindle runs at high speed. The use of electric spindle structure can make the spindle speed reach more than 10000r/min. The linear motor has high drive speed, good acceleration and deceleration characteristics, and has excellent response characteristics and following accuracy. The use of linear motor as servo drive eliminates the intermediate transmission link of the ball screw, eliminates the transmission gap (including backlash), the motion inertia is small, the system rigidity is good, and it can be precisely positioned at high speed, thereby greatly improving the Servo accuracy. Due to its zero clearance in all directions and very small rolling friction, the linear rolling guide pair has small wear and negligible heat generation, and has very good thermal stability, which improves the positioning accuracy and repeatability of the whole process. Through the application of linear motor and linear rolling guide pair, the rapid moving speed of the machine can be increased from the original 10-20m/min to 60-80m/min, or even as high as 120m/min.

High Reliability

The reliability is a key indicator of the quality of computer numerical controlled machine tools. Whether the machine can exert its high performance, high precision and high efficiency, and obtain good benefits, the key depends on its reliability.

CNC Machine Design with CAD, Structural Design with Modularization

With the popularization of computer applications and the development of software technology, CAD technology has been widely developed. CAD can not only replace the tedious drawing work by manual work, but more importantly, it can carry out design scheme selection and static and dynamic characteristic analysis, calculation, prediction and optimization design of large-scale complete machine, and can carry out dynamic simulation of each working part of the whole equipment. On the basis of modularity, the three-dimensional geometric model and realistic color of the product can be seen in the design stage. The use of CAD can also greatly improve work efficiency and improve the one-time success rate of design, thereby shortening the trial production cycle, reducing design costs, and improving market competitiveness. The modular design of machine tool components can not only reduce repetitive labor, but also respond quickly to the market and shorten product development and design cycles.

Functional Compounding

The purpose of functional compounding is to further improve the production efficiency of the machine tool and minimize the non-machining auxiliary time. Through the compounding of functions, the use range of the machine tool can be expanded, the efficiency can be improved, and the multi-purpose and multi-function of one machine can be realized, that is, a CNC machine can realize both the turning function and the milling process. Grinding is also possible on machine tools. Computer numerical controlled turning and milling compound center will work with X, Z axes, C and Y axes at the same time. Through the C axis and the Y axis, plane milling and machining of offset holes and grooves can be realized. The machine is also equipped with a powerful tool rest and a sub-spindle. The sub-spindle adopts a built-in electric spindle structure, and the speed synchronization of the main and sub-spindles can be directly realized through the numerical control system. The machine tool workpiece can complete all processing in one clamping, which greatly improves the efficiency.

Intelligent, Networked, Flexible and Integrated

The CNC equipment in the 21st century will be a system with certain intelligence. The content of intelligence includes all aspects of the numerical control system: in order to pursue the intelligence in machining efficiency and machining quality, such as the adaptive control of the machining process, the process parameters are automatically generated; in order to improve the driving performance and use the intelligence in connection, Such as feedforward control, self-adaptive operation of motor parameters, automatic identification of load, automatic model selection, self-tuning, etc.; simplified programming, simplified operation intelligence, such as intelligent automatic programming, intelligent interface, intelligent diagnosis, intelligent monitoring and other aspects to facilitate the diagnosis and maintenance of the system. Networked numerical control equipment is a hot spot in the development of machine tools in recent years. The networking of CNC equipment will greatly meet the needs of production lines, manufacturing systems, and manufacturing enterprises for information integration, and it is also the basic unit for realizing new manufacturing models, such as agile manufacturing, virtual enterprises, and global manufacturing. The development trend of computer numerical controlled machines to flexible automation systems is: from point (stand-alone, machining center and composite machining center), line (FMC, FMS, FTL, FML) to surface (independent manufacturing island in workshop, FA), body (CIMS, distributed network integrated manufacturing system), on the other hand to focus on the direction of application and economy. Flexible automation technology is the main means for the manufacturing industry to adapt to dynamic market demands and to rapidly update products. Its focus is to improve the reliability and practicality of the system as the premise, with the goal of easy networking and integration, and pay attention to strengthening the development and improvement of unit technology. CNC stand-alone machines are developing in the direction of high precision, high speed and high flexibility. CNC machines and their constituent flexible manufacturing systems can be easily connected with CAD, CAM, CAPP and MTS, and develop towards information integration. The network system develops in the direction of openness, integration and intelligence.